Samsung Nvidia Partner to Build AI Megafactory with 50000 GPUs for Full Automation

Samsung Nvidia Partner to Build AI Megafactory with 50000 GPUs for Full Automation

In a groundbreaking move, Samsung and Nvidia have officially announced a strategic partnership to construct an ultra-advanced AI megafactory that will revolutionize manufacturing through full-scale automation. The facility will be powered by a massive cluster of 50,000 Nvidia GPUs, integrating artificial intelligence across Samsung’s semiconductor, smartphone, and robotics production lines. This collaboration marks a new era in smart manufacturing, promising unprecedented efficiency and real-time optimization.

The announcement, made via a joint press release, reveals that the Samsung AI megafactory will function as a fully intelligent network, connecting every stage of production-from chip design and process engineering to equipment monitoring and quality assurance. By leveraging AI-driven predictive analytics, the system will continuously analyze vast datasets to anticipate issues, optimize workflows, and enhance output quality in real time.

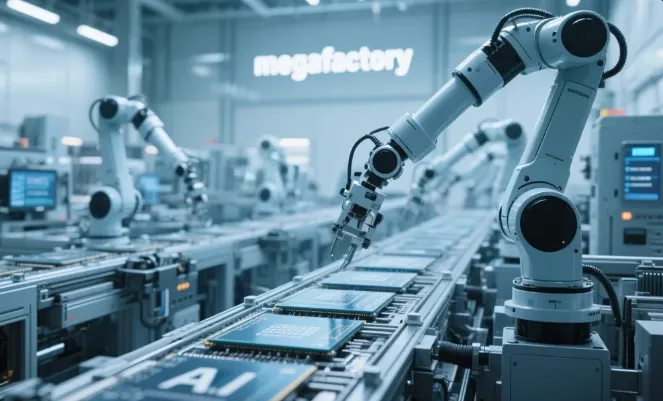

What is the Samsung AI Megafactory?

The Samsung AI megafactory represents the world’s most ambitious integration of artificial intelligence into industrial manufacturing. Unlike traditional automated factories that follow pre-programmed routines, this facility operates as a self-learning, adaptive ecosystem. At its core lies a supercomputing cluster of 50,000 Nvidia GPUs, forming one of the largest AI inference and training networks ever deployed in a production environment.

Samsung describes the megafactory as a “single intelligent network” where AI agents monitor and control every aspect of production. From wafer fabrication in semiconductor foundries to final assembly of Galaxy smartphones and advanced humanoid robots, the system uses machine learning models to predict equipment failures, optimize energy usage, reduce defects, and accelerate time-to-market.

The GPUs will run custom AI models trained on decades of Samsung manufacturing data, enabling hyper-accurate simulations of production scenarios. This allows engineers to test thousands of process variations virtually before physical implementation, drastically cutting costs and development cycles.

How 50000 Nvidia GPUs Will Transform Manufacturing

The deployment of 50,000 Nvidia GPUs creates a computational powerhouse capable of processing exabytes of sensor data per day. Each GPU cluster will be dedicated to specific tasks: design simulation, real-time process control, predictive maintenance, and quality inspection. Nvidia’s latest H200 Tensor Core GPUs and Grace CPU Superchips are expected to form the backbone, delivering up to 1,000x faster AI inference than traditional systems.

In semiconductor fabrication, AI will optimize lithography patterns, reduce wafer defects by up to 40%, and increase yield rates. For smartphone assembly, robotic arms guided by computer vision will achieve sub-millimeter precision, minimizing human error. In robotics R&D, the system will accelerate simulation of bipedal locomotion and dexterous manipulation, speeding up development of consumer and industrial robots.

Energy efficiency is another major focus. The AI network will dynamically adjust power consumption across fabrication plants, potentially reducing energy use by 25% during off-peak hours. This aligns with Samsung’s sustainability goals and reduces operational costs in an industry known for high power demands.

- Defect Reduction: Up to 40% in chip production

- Energy Savings: 25% through smart scheduling

- Yield Improvement: 15–20% in semiconductor lines

- Production Speed: 30% faster time-to-market

25-Year Partnership: From DRAM to AI Dominance

This isn’t the first collaboration between Samsung and Nvidia. Their partnership dates back over 25 years, beginning when Nvidia’s early GPUs powered Samsung’s DRAM modules in PCs and servers. Over decades, the relationship evolved into joint development of GDDR memory, HBM (High Bandwidth Memory), and foundry services for Nvidia’s data center chips.

Samsung Foundry has been a key manufacturing partner for Nvidia’s AI accelerators, producing chips used in data centers worldwide. The new AI megafactory builds on this foundation, but shifts the focus from product manufacturing to process intelligence. It represents a full-circle moment where Nvidia’s AI technology now enhances the very factories that build its hardware.

Samsung executives emphasized that this partnership goes beyond hardware supply-it involves co-developing AI algorithms tailored to semiconductor physics, materials science, and robotic kinematics. Nvidia’s CUDA-X libraries and Samsung’s process expertise combine to create domain-specific AI models unavailable elsewhere.

Impact on Semiconductor Industry

The Samsung Nvidia AI megafactory could reshape global semiconductor manufacturing. With AI-driven optimization, Samsung aims to widen its lead over competitors like TSMC and Intel in yield rates, cost efficiency, and production scalability. The technology may eventually be licensed to other foundries, creating a new standard for “Industry 5.0” factories.

Smaller chipmakers without access to such infrastructure may struggle to compete, potentially accelerating industry consolidation. However, the open nature of Nvidia’s platform suggests smaller players could adopt scaled-down versions, democratizing AI manufacturing tools over time.

Supply chain resilience also improves. By predicting equipment failures weeks in advance, the AI system minimizes downtime-a critical factor in an industry where a single day of halted production can cost tens of millions. This stability benefits downstream customers like Apple, Qualcomm, and Tesla.

Smartphone and Robotics Manufacturing Revolution

Beyond chips, the AI megafactory will transform Galaxy smartphone production. Assembly lines will use AI vision systems to detect microscopic defects in displays, cameras, and circuit boards. Adaptive robots will adjust torque and alignment dynamically based on material variations, ensuring consistent quality across millions of units.

In Samsung’s robotics division, the technology accelerates development of humanoid platforms like Ballie and industrial automation bots. AI simulations run 10,000x faster than physical prototypes, allowing engineers to test gait stability, object recognition, and safety protocols in virtual environments before building hardware.

The system also enables “digital twins” of entire factories-virtual replicas that mirror real-time operations. Engineers in Seoul can monitor and adjust a plant in Austin, Texas, with millisecond precision, enabling 24/7 global oversight.

Location and Timeline: What We Know So Far

Samsung and Nvidia have not disclosed the AI megafactory location or construction timeline. Industry analysts speculate it could be built in South Korea (near Suwon or Hwaseong), the United States (Austin, Texas), or a new greenfield site in Southeast Asia. Tax incentives, energy availability, and proximity to existing fabs will likely influence the decision.

Construction is expected to begin in 2026, with partial operations by 2028 and full deployment by 2030. The project involves thousands of engineers, data scientists, and robotics specialists, making it one of the largest tech infrastructure initiatives in history.

Power requirements will be immense-potentially exceeding 500 MW at peak load. Samsung is reportedly in talks with renewable energy providers to ensure carbon-neutral operations, aligning with global ESG standards.

Nvidia’s Growing Empire of AI Factories

The Samsung deal is just one of many for Nvidia, which recently surpassed $5 trillion in revenue-a milestone driven by explosive AI demand. Similar “AI factory” partnerships exist with Microsoft (Azure AI supercomputers), Intel (joint R&D on manufacturing AI), Nokia (5G edge AI), and OpenAI (custom training clusters).

Nvidia’s vision is to make AI the “new electricity” of industry. By embedding its GPUs into factories, cloud platforms, and edge devices, the company creates locked-in demand for future chip generations. This flywheel effect has made Nvidia the most valuable company in history, briefly surpassing Apple and Microsoft.

For Samsung, access to Nvidia’s latest silicon and software stack ensures it remains at the forefront of AI-driven innovation, even as competitors like TSMC invest heavily in smart manufacturing.

Challenges and Risks Ahead

Despite the promise, challenges remain. Integrating AI at this scale requires retraining thousands of workers, securing supply chains for rare-earth materials, and defending against cyber threats. A single breach could expose proprietary chip designs or halt production globally.

Geopolitical tensions also loom. U.S. export controls on advanced GPUs to certain countries could complicate expansion. Samsung and Nvidia must navigate these regulations while maintaining global operations.

Finally, the environmental impact of 50,000 GPUs running 24/7 cannot be ignored. Even with efficiency gains, the carbon footprint will be substantial unless offset by renewables.

The Future of Manufacturing is Here

The Samsung Nvidia AI megafactory is more than a factory-it’s a blueprint for the future of industry. By combining Samsung’s manufacturing scale with Nvidia’s AI leadership, the partnership sets a new benchmark for intelligent production. As AI permeates every layer of hardware creation, the line between design, simulation, and reality blurs.

For consumers, this means better chips, faster phones, and smarter robots. For investors, it signals sustained growth for both companies. And for the world, it heralds the dawn of truly autonomous industry-where machines don’t just build products, they invent better ways to build them.

While location and timeline details remain under wraps, one thing is clear: the Samsung AI megafactory will redefine what’s possible in technology manufacturing for decades to come.

Comment / Reply From

No comments yet. Be the first to comment!